Composition and Formation

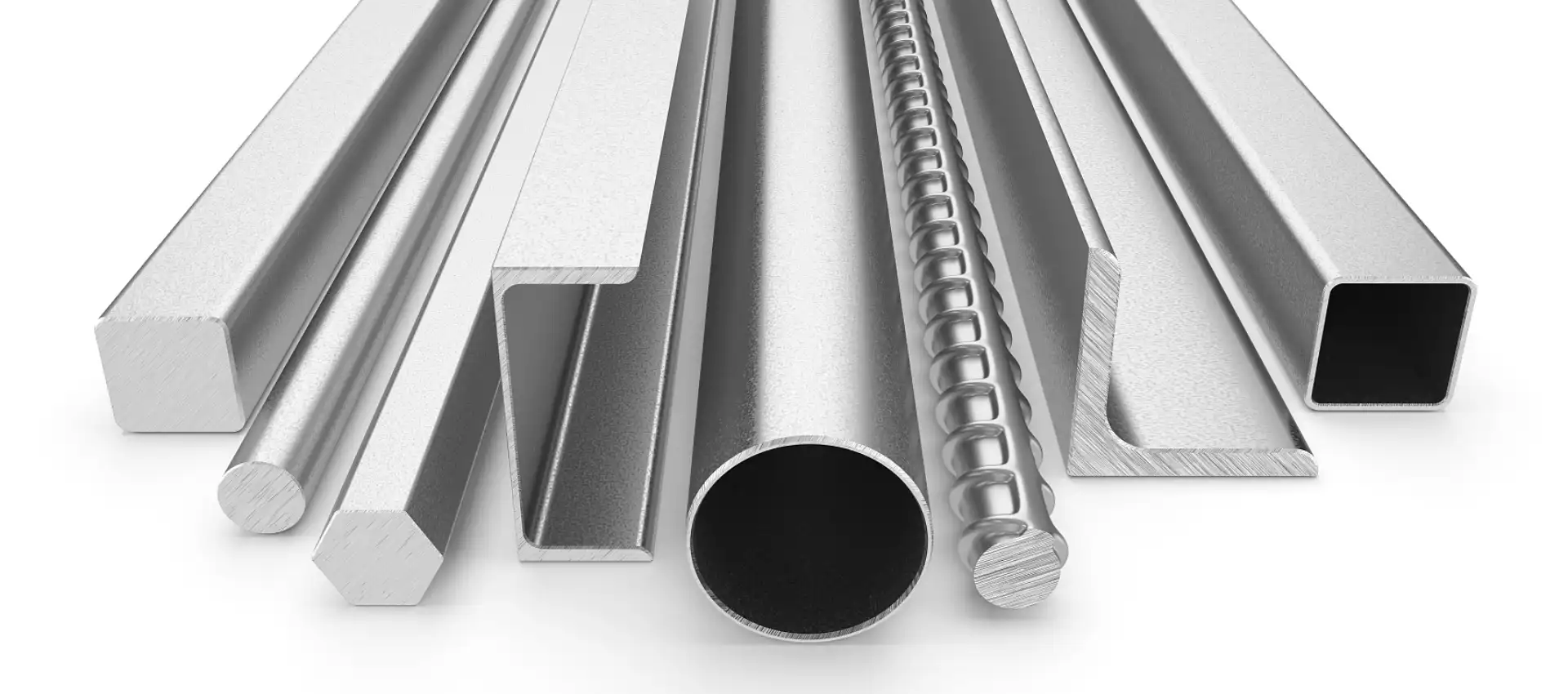

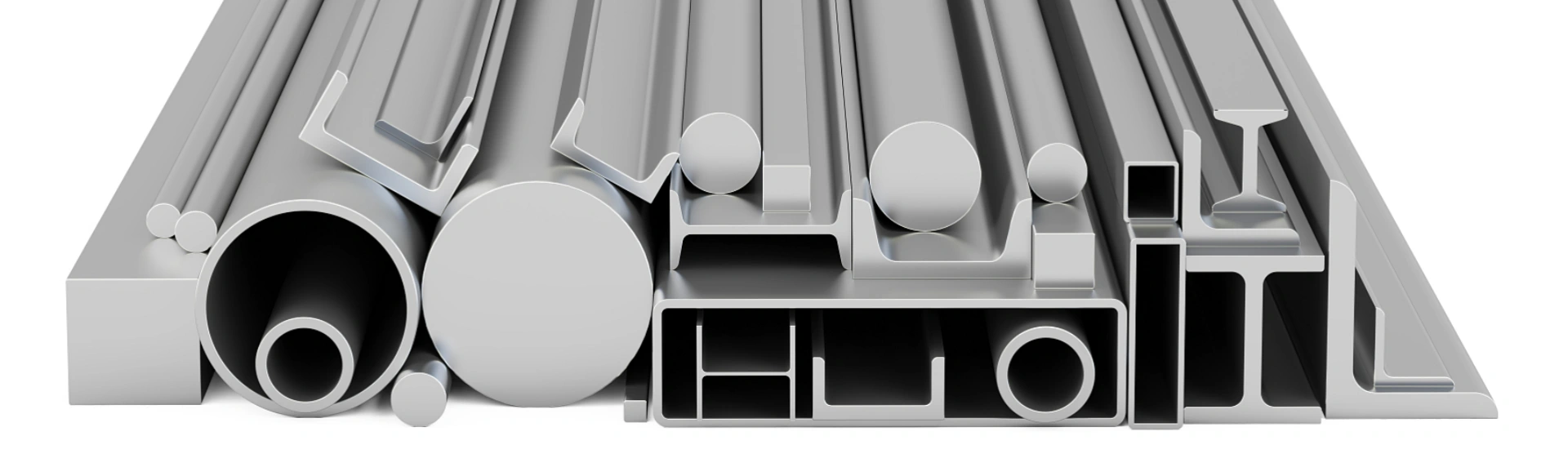

Alloy Steel:

In essence, alloy steel and stainless steel are like two sides of a coin, both indispensable in their own right. To make an informed decision, consider the unique demands of your project and choose the material that aligns with your priorities.

At Comely CNC, we specialize in precision CNC machining services, harnessing the power of alloy steel and stainless steel to craft components that meet your exact specifications. Our commitment to excellence ensures that your projects benefit from the strength, durability, and versatility of these materials. Contact us today to experience the precision of Comely CNC machining. Get A Quote Here

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China

NO.37 Tiancheng Road, Binjiang Development Zone, Nanjing, Jiangsu, China Тел./Whatsapp : +86-1377-0661-937

Тел./Whatsapp : +86-1377-0661-937 Электронная почта : sales@comelycnc.com

Электронная почта : sales@comelycnc.com